Production floors that once battled inefficiencies begin running smoother, energy costs drop, and coatings display a professional uniformity that speaks for itself. Across industries, well-engineered powder coating equipment transforms output quality and process speed in measurable ways that directly affect profit margins.

Throughput Boosted by Consistent Curing Cycles

In an advanced powder coating booth, consistency drives output. Precise temperature control within a propane powder coating oven ensures each part cures uniformly, eliminating variations in gloss or adhesion. Consistent curing not only enhances aesthetics but also shortens downtime between batches, keeping the production schedule tight and predictable.

Shops equipped with integrated temperature sensors and automated timers can move products through the curing stage at a steady pace. By maintaining even heat profiles, manufacturers prevent the uneven curing that leads to costly rework. This reliability translates into faster throughput and a more efficient production rhythm, paying back equipment investments quickly.

Material Savings from Reduced Overspray Loss

Powder loss during application is one of the most expensive inefficiencies in coating operations. Modern powder coating equipment with controlled airflows inside the industrial paint booth minimizes overspray by directing more powder onto the part and less into the atmosphere. That single adjustment significantly cuts material waste.

Powder reclaim systems now collect and recycle unused powder efficiently without contamination. By reducing material waste, manufacturers extend powder stock usage and lower overall costs per batch. A professional powder coating gun calibrated for precise output ensures consistent coverage while avoiding thick spots, further stretching material savings.

Finish Quality Stabilized Across Full Production

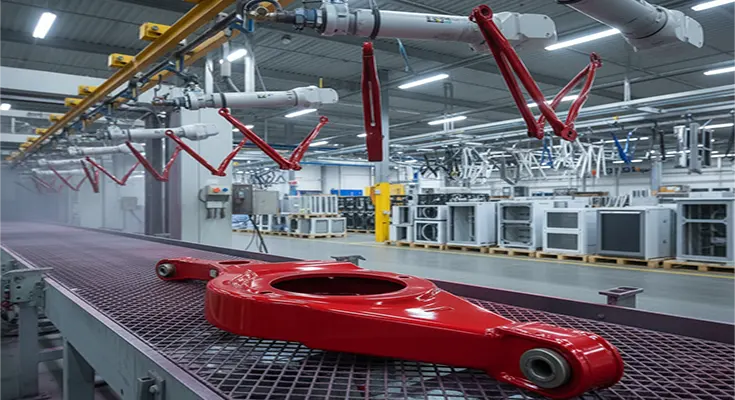

Consistency is where true return on investment emerges. With advanced powder coating systems, each piece—whether the first or the thousandth—leaves the production line with identical color depth and surface finish. A balanced combination of controlled airflow, static charge distribution, and oven temperature uniformity ensures the result never wavers.

In a modern powder coating booth, airflow patterns eliminate hotspots or dead zones that typically cause uneven coating thickness. The outcome is a stable finish that meets industry standards and reduces customer complaints or warranty claims. For manufacturers serving high-precision markets, such as automotive or aerospace, that stability alone can define competitive advantage.

Labor Strain Eased with Intuitive Spray Controls

Older systems often required extensive operator skill to maintain even coverage, but newer powder coating equipment simplifies that process through intuitive controls. Ergonomic spray guns with digital feedback give operators instant performance data, reducing fatigue and guesswork. With a professional powder coating gun, uniform coating becomes achievable even for less-experienced technicians.

Touchscreen interfaces and adjustable presets allow fast calibration for different powder types or part geometries. This user-friendly approach shortens the learning curve, reduces training time, and increases operator confidence. The reduction in physical and mental strain leads to higher productivity and fewer errors over time.

Color Changeovers Completed with Fewer Delays

In busy facilities that process multiple product lines, time lost during color changeovers can erode profitability. Advanced industrial paint booth designs include smooth interior surfaces and easy-access filters that simplify cleaning between colors. Newer powder coating booths use anti-static panels that repel residual powder, slashing cleanup times dramatically.

Modern spray systems also include quick-release hoppers and self-purging feed lines. These innovations allow faster color swaps without cross-contamination. Reducing changeover time not only increases daily production but also supports smaller batch runs—an essential feature for companies adapting to custom orders or just-in-time manufacturing.

Heat Retention Improved in Insulated Oven Chambers

Energy consumption makes up a major portion of operational cost, and insulated ovens offer immediate payback. A propane powder coating oven built with multi-layer insulation holds heat longer and recovers temperature quickly after door openings. This steady thermal efficiency minimizes energy waste and shortens cure cycles.

Improved insulation also protects exterior components, reducing ambient heat in the workspace and creating a safer environment for operators. Facilities equipped with energy-efficient ovens notice lower gas consumption and consistent curing temperatures that ensure uniform finishes, proving that smart design quickly offsets initial investment costs.

Scrap Rates Lowered Through Uniform Powder Application

Scrap and rework can quietly drain profitability. Advanced powder coating booths and guns mitigate this loss through controlled electrostatic fields that evenly attract powder particles to every contour of the product. This eliminates patchiness and reduces the chance of defects discovered after curing.

Automated application systems further stabilize coating density, producing predictable film thickness across multiple parts. The outcome is a dramatic reduction in wasted materials and rejected components. With consistent coverage from a professional powder coating gun, manufacturers can rely on first-pass yield improvements that directly increase margins.

Setup Time Shortened by Modular System Design

Older installations required extensive downtime for reconfiguration, but modular powder coating equipment now changes that equation. Adjustable booth panels, portable ovens, and interchangeable gun systems allow facilities to adapt production layouts without weeks of interruption. This flexibility is especially valuable for small to mid-sized operations scaling up or adding new product lines.

Modular design also simplifies maintenance. Technicians can replace filters, fans, or gun components without dismantling the entire unit. By shortening setup and maintenance time, these systems keep production running longer, reduce labor costs, and make expansion easier. For many facilities, this adaptability becomes one of the fastest-returning aspects of their investment.